Case Studies

Seavu

Product Design Case StudiesSEAVU

A revolutionary platform bringing cutting-edge underwater videography within everyone’s reach.

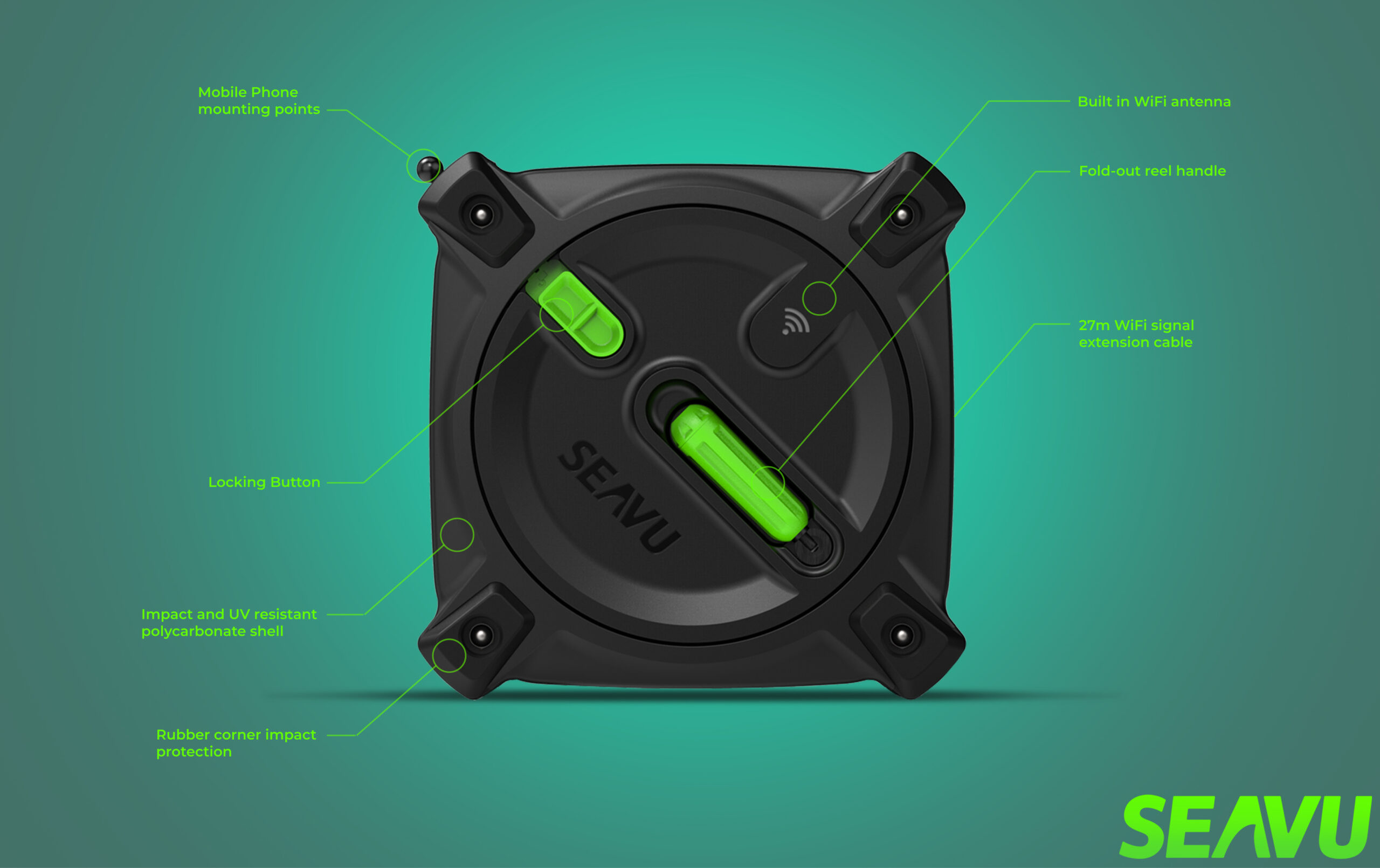

The SEAVU Explorer is the first product that makes underwater live-viewing and videography from a boat truly accessible to consumer markets.

Designed for a wide range of use cases, from boating and fishing to research and documentary filmmaking, it enables users to connect with the mysteries of the deep from the comfort of their boat.

Services delivered

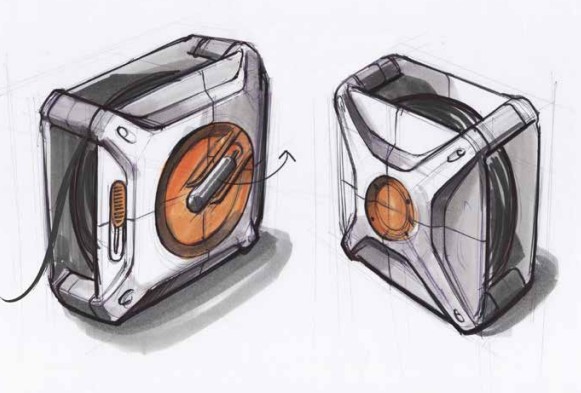

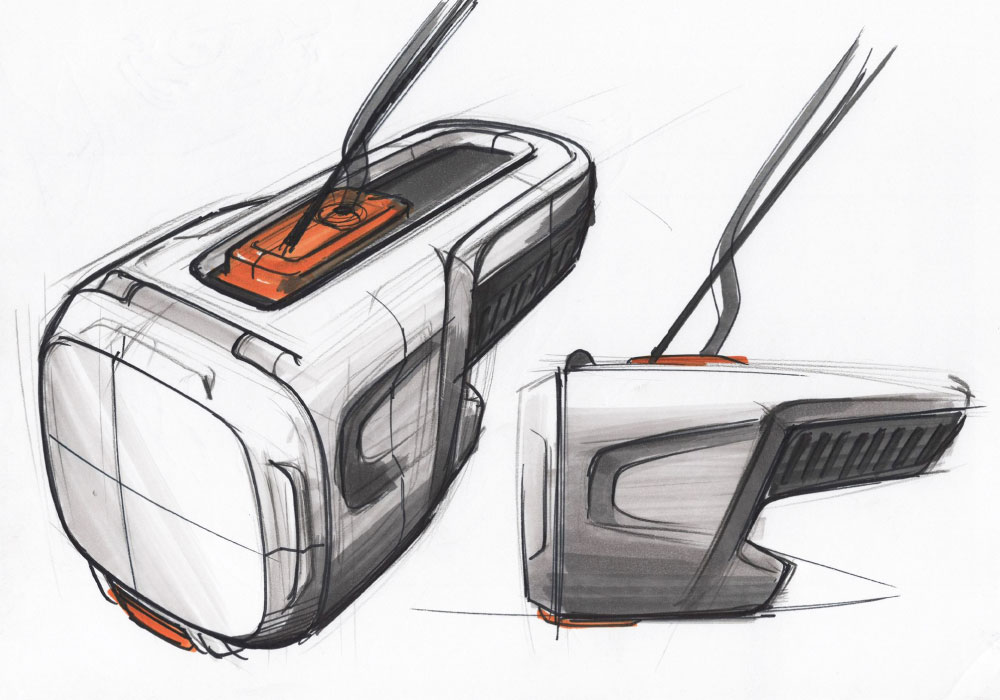

- Concept Development

- Industrial Design

- Product Engineering

- 3D rendering

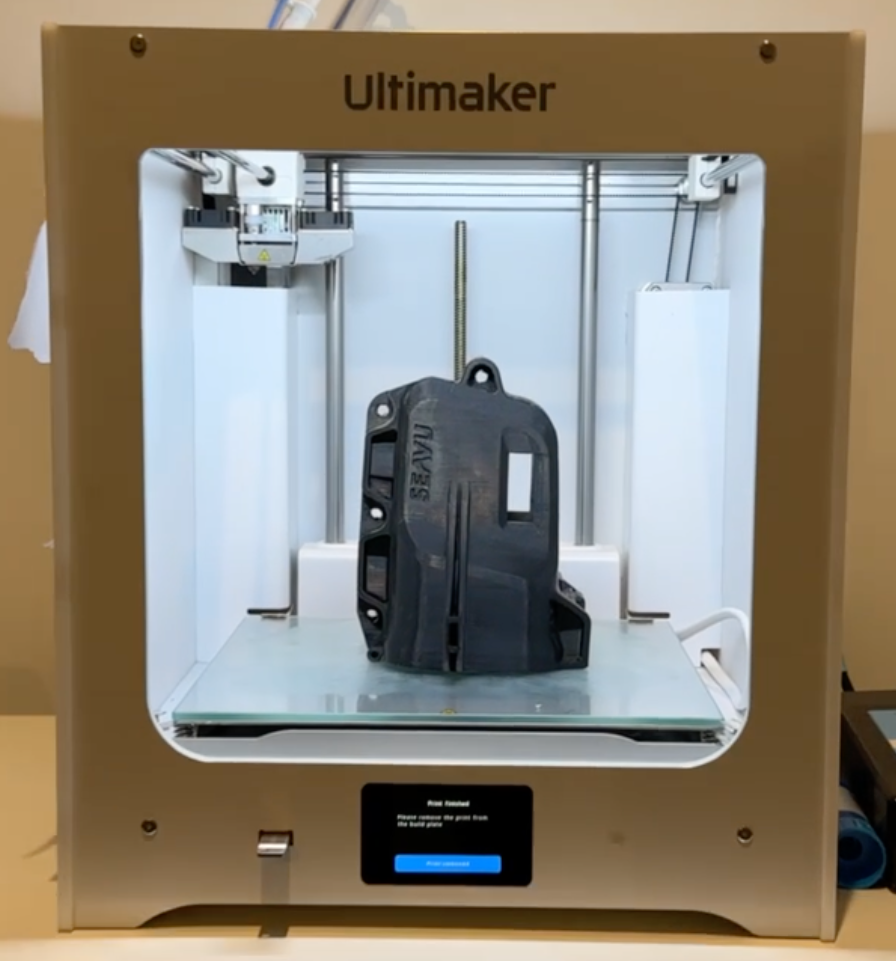

- Prototyping

- Environmental Testing

- Manufacturing & Sourcing

Project goals

SEAVU’s main goals were to fill a gap in the market for underwater and fishing camera technology while also making it more accessible to consumers.

- Bring cutting-edge underwater videography within everyone’s reach.

- Provide a more cost-effective platform for consumers.

- Allow users to connect their existing devices for underwater filming (even if they aren’t inherently waterproof).

- Support deeper underwater exploration.

- Adapt to a diverse range of use cases and industries (fishing, marine research, documentary making).

Features

- IP68 waterproof case.

- Compatible with smartphones, tablets or laptops.

- Also compatible with any off-the-shelf action camera like GoPro, Insta360 and DJI.

- Supports depths up to 50 metres.

- Passive WiFi Extension Antenna for live streaming up to 27 meters underwater.

- Real-time filming and monitoring capabilities.

- Modular accessory clips that enhance versatility and adaptability for various use cases.

Let’s bring your product to market

About the project

Why Our Clients Love Working With Us

Why Choose Us?

-

Work with our directors

Work with our directorsBy choosing Paraform, you can rest assured knowing our knowledgeable directors are overseeing your project from start to finish.

-

Reduce defects

Reduce defectsBy taking the time to test the nuts and bolts properly, we can assure you of a higher-quality product that’s well-crafted and unparalleled.

-

Nimble processes

Nimble processesWe’re a lean product engineering team based in Melbourne, and we pride ourselves on working quickly and efficiently at every stage.

-

End-to-end services

End-to-end servicesNo matter what stage your product idea has reached, we can help you bring a new product to market from the ground up, pronto.

Let’s bring your product to market