Our Process

Our End-to-End Industrial Design Process

No matter where you are in the journey towards bringing your product idea to life, we can help.

We offer end-to-end services that can be tailored to your specific needs, no matter if this is your first product idea or your 100th!

Below you can find out the details of our five industrial design phases, which will take you from conception through to production in no time. Or we can work with you on a specific phase depending on the level of design and research you already have completed.

No matter your needs, we’re with you every step of the way.

We’re small enough to care, yet big enough to help you succeed.

With over 30 years of combined experience, we have developed dozens of product ideas and helped bring innovative new products to market using the process detailed below. We’re experts at fusing art and precision engineering.

End-to-end product design

Friendly & approachable

Work with our directors

Cost-effective & ethical

Why Our Clients Love Working With Us

Industrial Design Stages: From Concept to Production

Step 1

Free Discovery Session

It all starts with a free discovery session with our directors. Together in this call, we detail the scope of your project and work out what’s needed to take your idea from concept through to production.

It’s a collaborative effort that fuses your idea with our expertise and knowledge. We will also ask you a series of questions and we can also collect any existing information and documents you may already have.

You’ll walk away with:

- A clear understanding of your idea’s feasibility

- A step-by-step blueprint for creating your market-ready product

Valued at over $500

Step 2

Concept Development

After our initial consult, we’ll get to work researching and provide you with a detailed design plan that overcomes key challenges for bringing your product to market.

We also test the feasibility of your product idea by reaching out to manufacturers for feedback on designs, a viability assessment, and to share their manufacturing expertise.

You’ll receive:

- Detailed Specifications Development

- Project Feasibility Study with Risk Mitigation Strategies

- Project Estimate with Options

- Manufacturing to Cost Validation

- Design Plan and High-Level Design Concepts

- Commercial Analysis

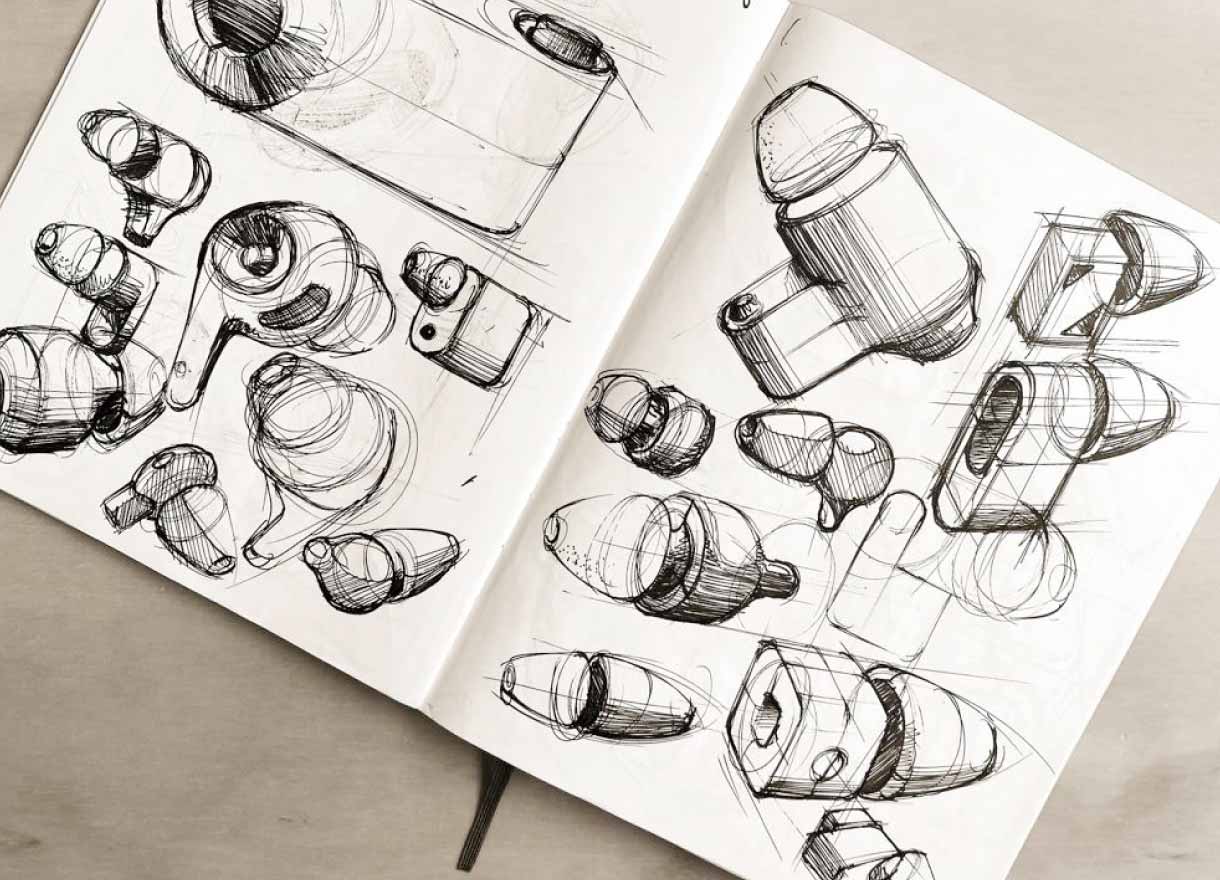

Step 3

Product Design

Using 3D modelling technology, we’ll start bringing your initial designs to life. We design for simplicity, elegance, quality and feasibility.

Taking the chosen concept design, we refine the design, applying mechanical engineering, ergonomics, regulatory requirements, cost targets and intended manufacturing methods.

In this phase, you’ll receive:

- Detailed design computer models

- Engineering models and drawings ready for prototype manufacturing

Are you just looking for help with bridging the gap from your concept designs to manufacturing?

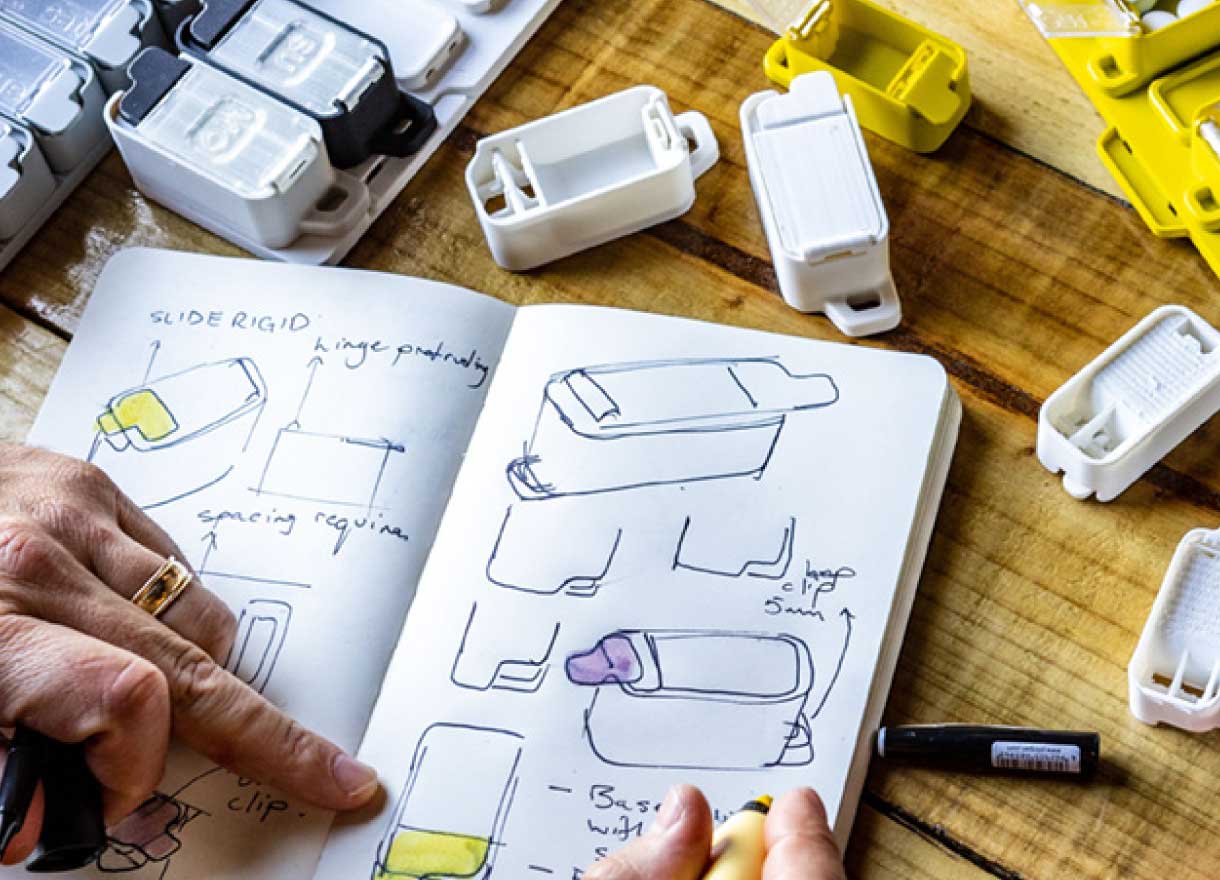

Step 4

Rapid Prototyping & Testing

Prototyping is an essential stage in the industrial design process as it allows us to work out any kinks before we start manufacturing your first product run.

We work closely with manufacturers to rapidly develop the first working prototypes of your product and to test them out. If adjustments to the design or concept are needed to improve your product, we will incorporate these as needed until your product is deemed ready for manufacturing.

In this stage, you’ll receive:

- Refinement of concept drawings into mechanical manufacturing files

- Sourcing & manufacturing of prototypes in 3 runs.

- Prototypes: We rapidly create a first working prototype of your product

- Revision: We revise and recreate your prototype

- Final Prototype: We settle on a final working prototype after addressing feedback

Check out our rapid prototyping service if all you need is a prototype and product testing before manufacturing.

Step 5

Manufacturing

With your completed design files and prototypes, we’ll collaborate with your manufacturer of choice to produce the first production run of your product.

Our directors will oversee the management of this process and provide you with weekly updates on progress.

Once the product is delivered, we will also conduct thorough quality control assessments to ensure the final product matches or exceeds the standard set out in the prototype run.

In this stage, you’ll receive:

- Finding and accessing manufacturer’s ability to meet project requirements

- Tooling required for production

- First-off-tool production parts

- Minor revisions

- First production run

Are you just looking for help with bridging the gap from your concept designs to manufacturing?