Case Studies

Jack Fuse

..better product design

than I had ever imagined.

Ken McKeon

JackFuse

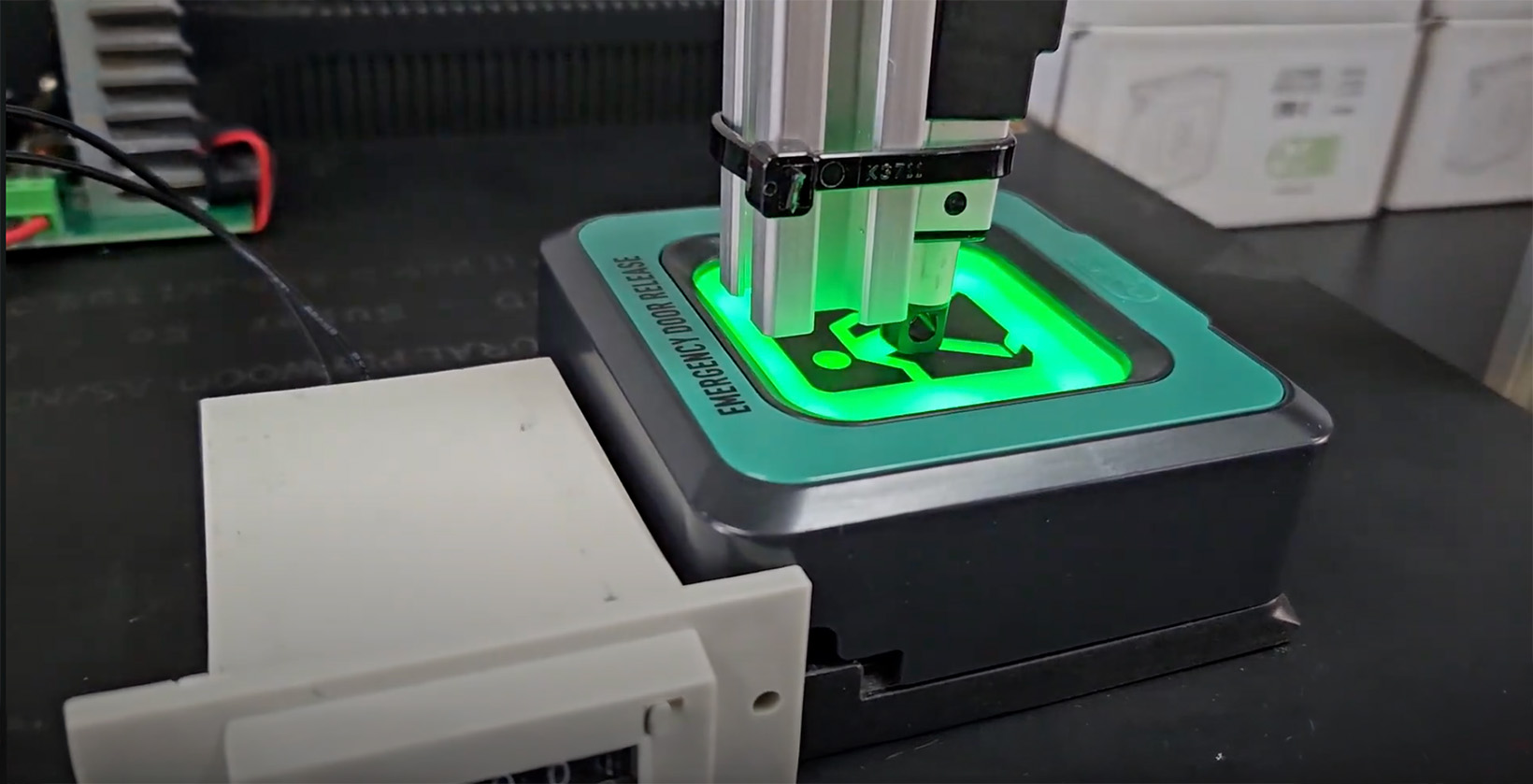

Revolutionising Emergency Door Release Systems with Remote and Automatic Reset Capabilities

The Jack Fuse Electronic Break Glass (EBG) represents a significant advancement in security technology, offering the first automatically and remotely resettable break glass unit. This innovative solution eliminates the need for manual site visits to reset emergency door release systems, reducing costs and enhancing security for fire safety providers and access control installers.

Services delivered

- Concept Development

- Industrial Design

- Prototyping

- Testing

- Manufacturing

Project goals

Jack Fuse’s main goals were to develop an advanced wall-mounted enclosure for the electronics security and access control market that would address critical limitations in existing break glass technology:

- Eliminate the need for manual site visits to reset break glass units

- Reduce operational costs associated with emergency door release maintenance

- Enhance security by minimising the time doors remain unlocked unnecessarily

- Create a retrofit-compatible solution for existing installations

- Target fire safety installers and security providers with an innovative alternative

Features

The Electronic Break Glass offers groundbreaking features that set it apart from traditional manual reset units:

- Multiple Reset Modes: Automatic, remote, and local reset with override capabilities

- Removable Activation Guard: Lift-up guard for added protection against accidental activation

- Advanced User Interface: LED backlighting with adjustable brightness and warning sounder with adjustable volume

- Enhanced Security Monitoring: Built-in tamper switch and two 3A contacts for door release and monitoring

- Retrofit Compatible: Footprint and mounting pattern matching legacy break glass units for ease of upgrade

- Robust Power Management: Low power mode operation with voltage tolerance down to 9V DC

Results

Industry Recognition and Media Coverage

- Featured in Security Electronics and Networks (SEN) publication, highlighting the innovative remote automatic reset capabilities

- Recognition for solving time and cost savings challenges in the security industry

Customer Testimonials

Ken McKeon provided a 5-star review of Paraform’s work: “The team at Paraform have an incredible ability to interpret my chicken scratchings and produce a better product design than I had ever imagined. Not only do they meet design requirements, they have also suggested enhancements and changes that have added real value to my products.”

Market Impact

- First-to-market solution offering automatic and remote reset capabilities for break glass units

- Addresses industry-wide challenge of manual reset requirements that previously necessitated costly site visits

- Provides retrofit compatibility, enabling easy upgrades for existing installations

Let’s bring your product to market

About the project

Why Our Clients Love Working With Us

Why Choose Us?

-

Work with our directors

Work with our directorsBy choosing Paraform, you can rest assured knowing our knowledgeable directors are overseeing your project from start to finish.

-

Reduce defects

Reduce defectsBy taking the time to test the nuts and bolts properly, we can assure you of a higher-quality product that’s well-crafted and unparalleled.

-

Nimble processes

Nimble processesWe’re a lean product engineering team based in Melbourne, and we pride ourselves on working quickly and efficiently at every stage.

-

End-to-end services

End-to-end servicesNo matter what stage your product idea has reached, we can help you bring a new product to market from the ground up, pronto.

Let’s bring your product to market